Beginners Guides

Carbon Footprint of Hydrogen Fuel

In assessing the environmental impact of hydrogen versus gasoline, it’s crucial to start by examining the energy consumption of hydrogen fuel. A single gallon of gasoline emits 9.1 kilograms of carbon dioxide. On the other hand, a kilowatt-hour of hydrogen generates only 0.28 kg of CO2. Hence, hydrogen fuel stands as an eco-friendly renewable energy source.

Hydrogen fuels have a carbon footprint

Hydrogen fuels could reduce the planet’s carbon footprint. According to BNEF’s “new Energy Scenario”, the world could consume 800 million tonnes of hydrogen by 2050. That would equate to 600 to 2,000 million tonnes of CO2 equivalent. It is important to remember that hydrogen released into the atmosphere could affect climate change and act as an indirect greenhouse gas. This could accelerate the buildup of methane or ozone.

The carbon footprint of hydrogen fuels depends on how they are transported and used. For example, it would cost more to transport hydrogen via pipelines than to transport it via sea. However, the cost of shipping hydrogen would be relatively stable at shorter distances, while that of hydrogen-powered ships would rise steeply with distance. In addition, hydrogen requires five times the amount of storage space compared to petroleum-based fuels. This could eat into cargo storage space and profits. A modelling study from earlier this year showed that hydrogen could power up to 99% percent of container ships on busy routes between China and the USA.

Although gray and blue hydrogen emit less carbon dioxide than natural gases, their carbon footprints are larger. Both types emit methane. However, these emissions are lower than those of other fossil fuels. Blue hydrogen produces more methane than gray hydrogen. However, they emit much less carbon dioxide than natural gas or coal.

While hydrogen can help a large extent in the near-term, it is important to remember that its mid-term warming impact is less than that of natural gas. To understand the impact of hydrogen on climate change, further research is needed to determine its greenhouse gas emissions. In the end, the role of low-carbon hydrogen in the hydrogen economy depends on its cost and how effectively it competes with hydrogen derived from fossil fuels. It must compete with hydrogen derived from fossil fuels and other forms of energy.

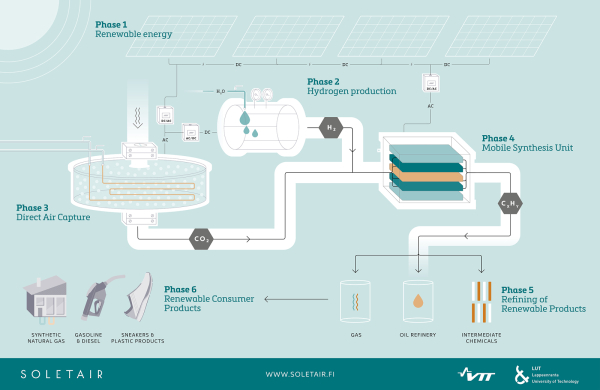

Electrolysis using renewable electricity is one way to make low-carbon hydrogen. Brown hydrogen, which is made from brown coal, is another carbon-intensive alternative. It can be produced by gasification and releases powerful greenhouse gases. Natural gas is another source of hydrogen and is produced by steam methane reforming. Around 95% of the world’s hydrogen is produced this way.

Hydrogen fuels’ life-cycle

When developing and manufacturing hydrogen fuels, it is important to consider the Life-cycle. There are many ways to make hydrogen. The most popular is steam reforming natural gas. Although this method uses fossil fuels, it is carbon-neutral if combined with carbon-capture and storage technology.

However, the carbon-intensive process of electrolysis can have a negative impact on the environment, even if the hydrogen is made from renewable sources. Hydrogen with low carbon intensity can be created by electricity from renewable sources. Nevertheless, the electricity grid mix in Europe is mostly fossil fuel-based, which impacts the carbon intensity of hydrogen.

Hydrogen can be produced on-site with electricity or natural gas, in addition to the hydrogen infrastructure facilities. It can also be transported by truck to a filling station. In both cases, the hydrogen is compressed and stored and then dispensed on demand to buses. To achieve this, hydrogen infrastructure facilities need to have a pressure differential between hydrogen storage tanks and vehicle tanks. The hydrogen supply may also need a booster mode. The compressors that are used to charge and complete filling can also be the same physical unit.

There are several ways to produce hydrogen, and all must be accounted for. The emissions from hydrogen production must also be considered in the Life-cycle of hydrogen fuels. These emissions will be emitted during the entire fuel’s lifecycle. It is therefore important to evaluate how hydrogen-fuel industry can help achieve a net zero energy future.

Although hydrogen-powered vehicles look promising, there are serious challenges. Hydrogen must be stored safely, in addition to security and environmental concerns. It must be stored in a highly compressed form, as a cryogenic liquid or as a chemical metal hydride such as sodium borohydride. Furthermore, fuel cell vehicles must have a way to safely transfer power from the fuel cell to the motor.

This technology is demonstrated in action by hydrogen buses. The first commercial hydrogen bus in the Netherlands was launched in November 2017 and is operated by Qbuzz, which is owned by Italian railways. The hydrogen used in this fuel station is produced at the Delfzijl Chemical Cluster’s AkzoNobel chlorine facility. It is then transported by tube-trailer truck.

Hydrogen production using renewable energy

The interest in using renewable energy for hydrogen fuel production has increased over the past few years. The world’s governments have set targets to produce hydrogen from renewable energy. Energy companies are also investing in this technology. California is one of the states that has enacted legislation to accelerate the use hydrogen fuel. Los Angeles is a leader in this area. The city has already committed to producing 80 percent of its own renewable electricity by 2030 and plans to achieve 100 percent by 2050. Moreover, the state has set a renewable hydrogen roadmap, including a new natural gas-fired power plant that could burn renewable hydrogen.

Hydrogen is made from natural gas, which currently accounts for a majority of industrial hydrogen production. This is a common practice, and is expected to continue for decades to come, but this practice is generating greenhouse gases and depleting fossil fuel reserves. A small amount of hydrogen can also be made using oil or electricity. The cost of hydrogen production from natural gas is affected by many factors, including the availability of gas and the price of electricity.

The construction of electrolyzers that generate large amounts of electricity is one of the largest costs in green hydrogen production. Transporting the fuel is another cost. This involves shipping and pipelines. While green hydrogen is not yet a mainstream fuel, there are several major projects underway in the country.

Hydrogen is a promising option for many urgent energy problems. Hydrogen is a promising solution to many pressing energy challenges. It can reduce emissions and increase energy security as we decarbonise the global economy. In addition, hydrogen can also improve air quality. It can also be used to reduce emissions in long-haul transport, chemicals, and other sectors.

Green hydrogen is not widely available and current projects are unlikely to meet demand. Currently, the projected global supply of green hydrogen is only three million tons annually. However, this figure is far from the goal of eight million tons per year. It is important to remember that green hydrogen does not solve all problems in decarbonizing our energy or industrial sectors.

Cost of transporting hydrogen fuels

The distance traveled will determine the cost of transporting hydrogen fuels. A long distance trip is expensive as hydrogen fuel is inefficient. The cheapest method to transport hydrogen is via pipelines. The cost to transport hydrogen fuel by pipelines is between US$2.5 and $4 per kilogram. For a short distance of three to five kilometers, a pipeline is the most cost-effective way to transport hydrogen fuel. The price of hydrogen fuel can vary depending on how far you travel and how much hydrogen is being transported.

Currently, the cost of chartering LNG ships averages $150,000 per day. The current cost of chartering LNG ships is $150,000 per day, with a projected increase to $350,000 by 2021. Liquid hydrogen costs less than LNG at $1 per cubic meter. And this is before the energy is converted into usable form.

However, shipping green hydrogen can be expensive. Transporting green hydrogen costs between $2-3/kg. To make hydrogen more mobile, it must be liquefied, compressed or combined with other elements. A zero-emission shipping method is essential to avoid high shipping costs.

Even though hydrogen fuels are cheaper than natural gas, transporting them is still expensive. Infrastructure is one of the greatest challenges. Many companies are looking at repurposing existing pipelines to transport hydrogen. They aren’t sure how this will work. They claim it will cost them ten to fifteen percent less than building new pipelines.

There are still several challenges that must be addressed before commercial hydrogen fuels can be adopted. The development of hydrogen infrastructure is slow. This is a major hurdle and will ultimately affect the cost of hydrogen fuel. The price of hydrogen fuels is determined by the amount of hydrogen delivered each day and the number refueling stations. This will require the cooperation and support of investors, national and local governments, and the hydrogen industry.

Despite its challenges, hydrogen can be used more widely. It is currently used mainly in oil refining and fertiliser production, but there is an opportunity for it to be widely used in transport, buildings, and power generation. The cost of hydrogen fuels could be comparable to other low-carbon options by 2030.

Hi, I’m David. I’m an author of ManagEnergy.tv where we teach people how to save energy and money in their homes and businesses.

I’ve been a writer for most of my life and have always been interested in helping people learn new things. When I was younger, I would write short stories for my classmates and teach them how to do math problems.

I love traveling and have been lucky enough to visit some fantastic places around the world.

Beginners Guides

Wind Turbines For Rooftops – Things You Should Know

Wind turbines offer a proficient method to produce energy and reduce your expenses. However, prior to mounting them on your rooftop, there are several aspects you ought to be aware of.

First and foremost, they may not be suitable for every property. Not only can they be unsightly, but their noise levels may irritate your neighbors as well.

They’re a renewable energy source

Rooftop wind turbines are an affordable and eco-friendly way to generate renewable energy for your home. Not only do they reduce energy bills, but they also contribute towards combatting climate change!

They require zero electricity to run, making them an ideal option for homeowners living in rural areas or places where connecting to the power grid may be challenging. Furthermore, wind turbines use wind energy to generate renewable energy on cloudy days or nights when solar panels aren’t producing much output.

Before deciding whether or not to install a wind turbine on your roof, there are several factors you should take into account. Most importantly, assess the quality of wind in your area.

Wind is typically found higher up, away from trees or other objects that could cause turbulence. Your turbine will last longer and produce more energy if placed where there’s laminar wind (wind without much turbulence) rather than turbulent ones.

Before installing a wind turbine on your rooftop, it’s wise to research local laws and regulations. Some places may have limits regarding how many turbines can be placed there or even the height at which they must be placed.

At present, there are two primary types of wind turbines used for wind power production: horizontal-axis wind turbines (HAWTs) and vertical axis wind turbines (VAWTs).

HAWTs are commonly used on rooftops, but VAWTs can be more efficient when installed at lower elevations. Furthermore, these turbines tend to be smaller and easier to install than their HAWT counterparts.

A rooftop wind system could solve these issues by using aerodynamics similar to airplane wings to capture and amplify air flow on rooftops. This motionless technology, called AeroMINE, can be combined with solar panels for a completely green energy source.

They’re a good investment

Installing a wind turbine on your roof is an excellent way to cut energy costs and contribute to the environment. But before making such an investment, there are several things you should take into account.

Before anything else, it’s important to understand how much energy can be generated with a wind turbine. Most small models range between 400W and 1kW, meaning they can generate between 24 kWh of electricity daily (assuming the wind blows consistently at this speed).

However, this is not always the case. Turbulent winds tend to be less effective than laminar wind – air that has consistent speed and direction.

For optimal energy production, wind turbines should be placed in an unobstructed location that receives consistent, unobstructed wind. Unfortunately, living in a city may not provide this option since wind tends to blow in different directions and be more unpredictable.

Due to this, if your wind turbine cannot generate enough power from the environment, solar panels might be a more suitable option.

Solar panels can reduce your energy bills and even provide some of the power you need for running your home, especially if your local power company has an agreement to buy back any excess produced or you own an electric car.

Solar panels are more costly than wind turbines and must be installed on a property suitable for them. While it’s possible to connect a wind turbine to the grid, this requires an expensive upfront investment and only works in remote areas without access to electricity.

Finally, you should also be mindful of the noise your turbine will generate. Generally, small wind turbines won’t be any louder than your air conditioner, but they may generate vibrations which could weaken your roof structure.

Furthermore, rooftop wind turbines should never be installed on structures not intended to withstand the stresses and vibrations they cause. This is a sound rule of thumb for any kind of roof construction – not just those containing wind turbines.

They’re a good way to reduce your energy bills

Rooftop wind turbines are a renewable energy source that can drastically reduce your energy bills, especially if you live in an area with abundant wind power. Not only that, but these windmills also help you become more energy independent and reduce your carbon footprint.

Wind turbines, unlike solar panels that must be placed near the sun to work, can operate in any condition – even at night and with cloudy weather. That’s why they’re often combined with solar technology to generate electricity.

Rooftop wind systems can be an appealing prospect for both homeowners and businesses, but they come with their share of challenges. The primary one lies in making sure the turbines are spaced correctly so as not to collide and cause damage to your roof.

Aeromine has developed a rooftop wind turbine that utilizes the same aerofoil-based design used by airplane wings to lift themselves off the ground. This system, still in development, harnesses the same power as towering turbines but is much easier to install on homeowners’ roofs.

This approach relies on the fact that wind turbines don’t need to move as much as traditional ones do, meaning they could be placed closer together. This could help keep the equipment from producing excessive noise or vibration – a major drawback of other types of wind-powered systems.

Furthermore, a smaller device would not have to worry about getting damaged due to high winds that can wreak havoc on larger turbines. That makes it an ideal choice for areas with high levels of wind shear, which may weaken their power output.

However, installing a small rooftop wind turbine may not be worth the cost if you’re already connected to the grid and don’t require it for additional electricity production. According to EST estimates, an average household with a PS2,000 pole mounted turbine would only generate around 9,000 kilowatt hours of energy annually – not enough to significantly reduce your bill.

They’re a good way to save money

Wind power for home use is an efficient way to reduce energy bills and cut back on carbon footprint, thus lessening its environmental impact. But before you install a wind turbine on your roof, there are some things you should be aware of.

Wind power is a renewable resource, meaning that it doesn’t produce any pollutants or other hazardous chemicals. This makes it especially ideal for homeowners looking to live green and reduce their carbon footprints.

If you’re in search of a wind turbine for your rooftop, opt for one that generates an impressive amount of electricity. Smaller turbines won’t supply enough power to meet all your household demands.

Another factor to consider is tower height. To maximize the power of your turbine, it’s necessary for it to be at least 80 feet high; otherwise, you won’t get optimal performance from it.

Before making your final decision, it’s important to give careful thought to this factor. A taller turbine will be more efficient and there is less chance of it falling off the roof or damaging your property.

You should take into account the noise level generated by a wind turbine. While you don’t necessarily need to worry about this immediately, if your sensitivity to noise is any, then it’s worth taking into account.

In most cases, ambient sounds from your neighborhood and traffic will drown out the sound of a small wind turbine. However, turbulence amplifies vibrations so you may still hear it.

If you want to cut costs on your energy bill even further, installing a wind turbine for your roof is an ideal option. This is particularly true if combined with other renewable sources of energy like solar panels.

Wind turbines can be an excellent way to save money, but they may not be suitable for everyone. Some people find them unattractive and some neighborhoods find them undesirable. Before making the decision to install a wind turbine, do your research and discover what other clean energy options exist in your area.

Hi, I’m David. I’m an author of ManagEnergy.tv where we teach people how to save energy and money in their homes and businesses.

I’ve been a writer for most of my life and have always been interested in helping people learn new things. When I was younger, I would write short stories for my classmates and teach them how to do math problems.

I love traveling and have been lucky enough to visit some fantastic places around the world.

Beginners Guides

Wind Turbines As a Power Source For Camping

Wind turbines serve as an outstanding energy solution for camping adventures because of their transportability, environmental friendliness, straightforward setup, and reliability. They are a perfect option for those seeking a sustainable choice that is also economical.

Solar batteries can also provide you with energy during days when solar panels aren’t producing much power. But before making a decision, it’s essential to understand their advantages and potential drawbacks.

Portable

Campers, RVers and off-grid travelers know how challenging it can be to locate a reliable power source. The last thing you want is to emerge from your tent only to discover that your phone or tablet has run out of juice.

If that occurs, you’re in trouble. Fortunately, there is a solution: portable wind turbines for camping that can charge your devices and store power for later use.

You have your pick of portable wind turbines, all designed with portability in mind and easy setup. Most have smaller rotor diameters and detachable blades which make them convenient to store or carry when traveling.

Many portable wind turbines are water resistant, meaning they’re more durable in adverse weather conditions. This is especially beneficial if you live in areas prone to flooding or mud slides.

Another advantage of portable wind turbines is their ease of assembly and dismantle. This is especially helpful if you’re traveling by car and need to switch campsites frequently.

Some wind turbines are even small enough to fit in a backpack, making them perfect for outdoor adventures. Plus, many allow you to charge your phones and other gadgets while hiking or camping in the wild.

For instance, Aurea Technologies’ Shine turbine is a 40-watt wind charger that can power phones, tablets, lights, drones and cameras in real time or store energy for later use. Setting up takes less than two minutes and includes pegs for mounting the device on the ground.

Furthermore, the Shine turbine’s internal 12,000 mAh battery can charge three or four mobile phones simultaneously, helping you save money by cutting back on electricity usage.

Wind turbines for camping are renowned for their eco-friendliness. Not only do they produce clean, renewable energy, but they are made from non-toxic materials as well. This is especially valuable to people who care about the environment and want to contribute towards finding solutions.

Eco-friendly

Camping trips offer an ideal opportunity to reconnect with friends and family, but can be challenging without access to clean, renewable energy sources. That’s where portable wind turbines come into play; these devices are eco-friendly and can power any number of appliances or electronic devices, allowing campers to relax in nature without worrying about their power source.

These generators offer a superior alternative to fuel-based generators that need frequent refilling and can become costly over time. Furthermore, their lack of carbon emissions makes them ideal for the environment.

These renewable energy devices work by converting kinetic energy into mechanical power through a turbine’s rotor blades. Usually made out of steel, these blades can be installed on a pole to capture wind power.

Wind turbines are generally inefficient, but can still provide a valuable source of sustainable energy when combined with solar panels and other off-grid options. Unfortunately, they don’t produce as much power as other off-grid sources and won’t cover all your needs if camping in an area with optimal wind speeds.

It’s also essential to avoid installing wind turbines near your RV, as they could serve as a lightning rod and increase the risk of storms. While this may not be a major concern for most people, if you want to be environmentally conscious on your next camping trip then this should be taken into consideration.

Some campgrounds in New Mexico are taking an eco-friendly approach by installing wind and solar power systems to keep their facilities running smoothly. They’re showing that it’s possible to combine sustainable energy production with a fun outdoor experience.

One of the advantages of these renewable energy devices is their affordability and accessibility for campers. They’re small enough to fit in a backpack and can provide power to many small appliances or electronic gadgets.

They’re perfect for charging GPS units and other portable electronic devices on the go, making them a must-have item on any camping gear list and an essential item for eco-conscious campers looking to reduce their environmental impact.

Easy to install

If you’re searching for a sustainable energy source to fuel your camping trip, wind turbines are an excellent option. They generate enough electricity to charge batteries and run electronics all day and night. Furthermore, wind turbines offer cost-effectiveness while being environmentally friendly solutions.

Wind turbines are incredibly simple to install and many can be mounted directly on your roof. Alternatively, they can be purchased as standalone units that sit outside your home or rig and require no special tools or knowledge for setup.

Finding the ideal wind turbine for you requires some research. Consider your power needs, camping style and current electrical setup when making this decision.

You should also consider how much you want to save on energy expenses. A calculator can help determine how much money could be saved with your new turbine, so that you can determine if it is the right choice for your family.

Once you’ve decided that wind turbines are the right option for your property, the next step is deciding where they should be situated. This step is essential in ensuring they produce enough electricity.

Another essential factor to consider is the amount of wind in your area. Most turbines need at least 20 mph winds to operate, so make sure there are no large objects or trees blocking the breeze.

It is also essential to remember that wind turbines require regular upkeep. These devices need to be serviced and checked for functionality to guarantee they run optimally.

If you’re not sure how to begin, read the manual that comes with your unit as it will guide you through each step and help determine if you feel confident with the procedure.

If you’re considering installing a wind turbine, it is best to hire an experienced professional for the job. This will guarantee your wind turbine is properly installed and provides you with top-notch results.

Reliable

Wind turbines are an ideal solution for RVers who want to save money and reduce their carbon footprint while traveling.

They provide a convenient way to recharge your electronics and mobile devices, but you should be aware that they may produce some noise. This noise may be irritating if you have sensitive ears.

Another disadvantage is that wind turbines require a certain amount of wind to reach their maximum output. Therefore, you should select an area likely to experience strong winds.

Many campers avoid dealing with this issue, as it can negatively impact their trip. That is why researching your options before making a decision is so important.

A top-tier RV wind turbine should boast a high capacity and wide operating temperature range, as well as being lightweight and long-lasting.

These features will guarantee your wind turbine is reliable for a long time, which is especially critical for campers who are constantly on the go.

These features will make operating your wind turbine much simpler. They reduce the likelihood of malfunction or other issues that could leave you running out of energy.

Are you in search of a dependable RV wind turbine? Marsrock’s Small RV Wind Turbine Generator is your perfect choice. This model boasts an impressive 20-year lifespan, charge controller, and simple installation instructions for added convenience.

This RV battery charger features an operating temperature range of -40C to 80C, making it suitable for any weather conditions RVers may encounter on their journey. Plus, its charger can handle both 12V and 24V systems simultaneously, giving you complete customization to suit your individual needs.

RV wind turbine owners appreciate its durable design, lightweight construction and low start-up speed. It’s no wonder why this model has become such a popular choice among them.

Hi, I’m David. I’m an author of ManagEnergy.tv where we teach people how to save energy and money in their homes and businesses.

I’ve been a writer for most of my life and have always been interested in helping people learn new things. When I was younger, I would write short stories for my classmates and teach them how to do math problems.

I love traveling and have been lucky enough to visit some fantastic places around the world.

Beginners Guides

Wind Turbine Life Expectancy

The longevity of wind turbines is influenced by multiple variables, such as their placement, upkeep needs, and the surrounding environmental circumstances. Typically, under optimal conditions, they are expected to have a service life of 20 to 25 years.

Most turbines possess service life reserves that can be extended beyond their original design lifespan with relatively minor, cost-effective repairs. This provides operators with an opportunity to generate revenue for longer periods of time.

Cost

Wind turbines are a long-term investment, which requires ongoing upkeep. While the initial cost may be high, if you live in an area with generous wind incentives, your return on investment should be positive over time.

Wind turbine life expectancies are determined by a variety of factors, including environmental conditions and fatigue as well as regular maintenance. Damage from lightning strikes, birds or collisions, ice or snow can significantly reduce energy output from these devices.

A turbine’s life span can be affected by its location and the quality of materials used. For instance, wind turbines installed in high-wind regions typically last longer than those situated in low wind areas.

Wind turbines typically have a design lifespan of 20 years, though this number can change based on various factors. For instance, local wind conditions may differ from what was intended when the turbine was initially created or expansions at nearby wind farms may increase turbulence.

These changes can significantly shorten a wind turbine’s lifespan. Estimates suggest that those installed within the last decade won’t make it to their 20-year mark, and even if they do, it is highly unlikely they will function at full capacity.

Wind farm operators must decide whether to keep operating the turbines or decommission them completely. This could involve an expensive process of taking apart and dismantling the turbine, selling or recycling valuable parts and then repowering with more modern technology.

Decommissioning old turbines can be expensive; replacing them with more energy-efficient models requires extensive research and development before these systems can be constructed at low prices.

Another way to reduce decommissioning expenses is recycling as many of a turbine’s materials as possible during its lifespan, especially blades which contribute significantly to energy loss.

Tens of thousands of outdated blades are discarded annually around the world, mostly in North America and Europe. The problem is getting worse as more turbines are constructed with shorter and longer towers for increased energy production. Unfortunately, much of this waste is non-recyclable and will end up in landfills where its fiber-reinforced plastic composition won’t break down easily.

Environmental conditions

The life expectancy of a wind turbine is determined by several environmental conditions. These include weathering, icing, lightning strikes, bird and insect collisions and structural damage to the blades or nacelle of the turbine. All these factors can cause it to break down prematurely, decreasing its energy output by up to 25%.

On average, wind turbines have a lifespan of 20 to 25 years; however, this may not be true for all farms. Some sites are more vulnerable to harsh environmental conditions than others and thus experience premature breakdown.

Another factor that may reduce a wind turbine’s life expectancy is how often it needs maintenance. Regular checks, including lubrication and replacement of worn parts or repair of damaged components, can significantly extend their service lives.

However, if a wind farm is unable to adequately maintain its turbines in an efficient and safe way, decommissioning may eventually be necessary. The decision for decommissioning must be site specific and take into account technical, economic and regulatory considerations.

One solution to this issue is recycling decommissioned blades. Some cities in the US have turned their decommissioned blades into playgrounds and other recreational spaces, while in Cork, Ireland the blades are being recycled into raw materials for cement manufacturing.

This is an important step, as it reduces the environmental impacts associated with landfilling waste. Furthermore, it enables more efficient disposal processes and minimizes potential air pollution caused by landfilling composite material waste.

In addition to this, there are other methods available for recycling and disposing of end-of-life wind turbine blades. These include:

The environmental effects of wind turbine manufacturing, transportation, on-site construction and assembly, operation and decommissioning can be greatly reduced if appropriate measures are taken at each step. To do this, an LCA study should be performed for each major stage. This will identify key stages that contribute most to overall environmental damage caused by a turbine and identify critical ones which can be redesigned with reduced negative effects in mind.

Maintenance

Wind turbines are complex machines requiring regular upkeep to stay operational. Preventative maintenance aims to extend their lifespan by making repairs or replacements before the equipment fails, while predictive maintenance utilizes monitoring systems that place sensors at key points within the machinery and send data back to the maintenance team for analysis.

Monitoring systems can identify any failures before they become more severe, helping reduce the costs of unscheduled stoppages, crane and repair equipment rental fees and revenue loss. For instance, if a turbine blade fails, there will be significant downtime and revenue loss from having to hire cranes to transport both the damaged component and technicians to a repair site.

Manufacturers typically recommend regular maintenance intervals for wind turbines, however these are often insufficient to keep them running optimally and securely. Inspections on a regular basis are essential in order to detect issues before they become more serious.

Most wind farm operators employ both preventive and predictive maintenance strategies to extend the life of their assets. Preventative work includes cleaning, lubrication, adjustments, and repairs; while predictive monitoring relies on sensors to track turbine condition and alert workers when it is time for a checkup.

With advances in technology, predictive maintenance is becoming a more commonplace practice. For instance, wind turbines can now be equipped with sensors that monitor lubrication levels, vibration levels, temperatures and foundation displacement – enabling workers to identify any issues early on.

Wind turbines can be highly complex and challenging to maintain due to their often remote locations, necessitating technicians to travel far distances for maintenance. Furthermore, since wind turbines typically rise 300 feet above the ground, there may be potential safety risks when working on the equipment.

Contemplating realistic maintenance plans and costs as part of project development is essential. Ideally, the contract phase should include a detailed discussion about operation and reliability data sharing with the turbine manufacturer; this will guarantee all parties are aware of specific component failure modes and can negotiate what post-warranty options exist to protect the asset.

Replacement

The life expectancy of a wind turbine is determined by several factors, including its location and environment. All these elements can influence its lifespan, so it’s essential to take them into account when planning any project.

On average, wind turbines have a lifespan of 20 years. If designed and maintained properly, then these machines should last much longer. Unfortunately, many wind farms fail due to various reasons.

One of the primary causes of wind turbine failure is wear and tear. This occurs due to exposure to harsh weather conditions, which can eventually lead to breakdown.

Therefore, it is imperative to replace a wind turbine as soon as possible when it starts malfunctioning. Doing this prevents you from losing valuable energy that could have been used for powering your home or business.

Additionally, you will save on the costs of replacing the turbine. A brand-new wind turbine is much more affordable than having to repair or replace an outdated model.

It is also worthwhile to remember that wind turbine components typically have a design lifetime estimate. If you plan on running your wind turbine for an extended period, then it is essential to take into account each component’s predicted lifespan.

The design lifetime of each component is determined by the materials used and their ability to withstand adverse conditions. For instance, rotor blades are usually constructed to withstand hurricane-force winds.

Another factor is the location of a component. This can influence how easy it is to repair it. If something is inside the turbine, for example, then access and maintenance may be difficult.

Thankfully, the industry is moving toward modular components. This makes replacing a wind turbine simpler since there’s no need to incur expensive labor expenses.

Hi, I’m David. I’m an author of ManagEnergy.tv where we teach people how to save energy and money in their homes and businesses.

I’ve been a writer for most of my life and have always been interested in helping people learn new things. When I was younger, I would write short stories for my classmates and teach them how to do math problems.

I love traveling and have been lucky enough to visit some fantastic places around the world.

-

Sustainable Supply Chain Management2 months ago

Sustainable Supply Chain Management2 months agoManagEnergy Acquires GPST2030.org Domain to Strengthen Commitment to Sustainable Transport

-

Wind Energy2 months ago

Wind Energy2 months agoHow Much Oil Does It Take To Lubricate A Wind Turbine

-

Electricity Vehicle2 weeks ago

Electricity Vehicle2 weeks agoThe Future of Electric Vehicles: Trends and Innovations to Watch

-

Electric Motorbike1 week ago

Electric Motorbike1 week agoCalifornia Electric Motorcycle Laws: A Comprehensive Guide to Riding Safely

-

Solar2 months ago

Solar2 months agoIn 2009, About What Percent Of U.S. Energy Consumption Was Supplied By Solar Energy

-

Wind Energy2 weeks ago

Wind Energy2 weeks agoEnvironmental Innovation Turned Deadly: Ocean Wind Turbines Pose Threat to Whales’ Survival

-

Wind Energy1 week ago

Wind Energy1 week agoRevolutionizing Highways: Wind Turbines Take the Road to Renewable Energy

-

Solar2 months ago

Solar2 months agoWhy Should We Use Solar Energy Instead Of Fossil Fuels