Solar Cells

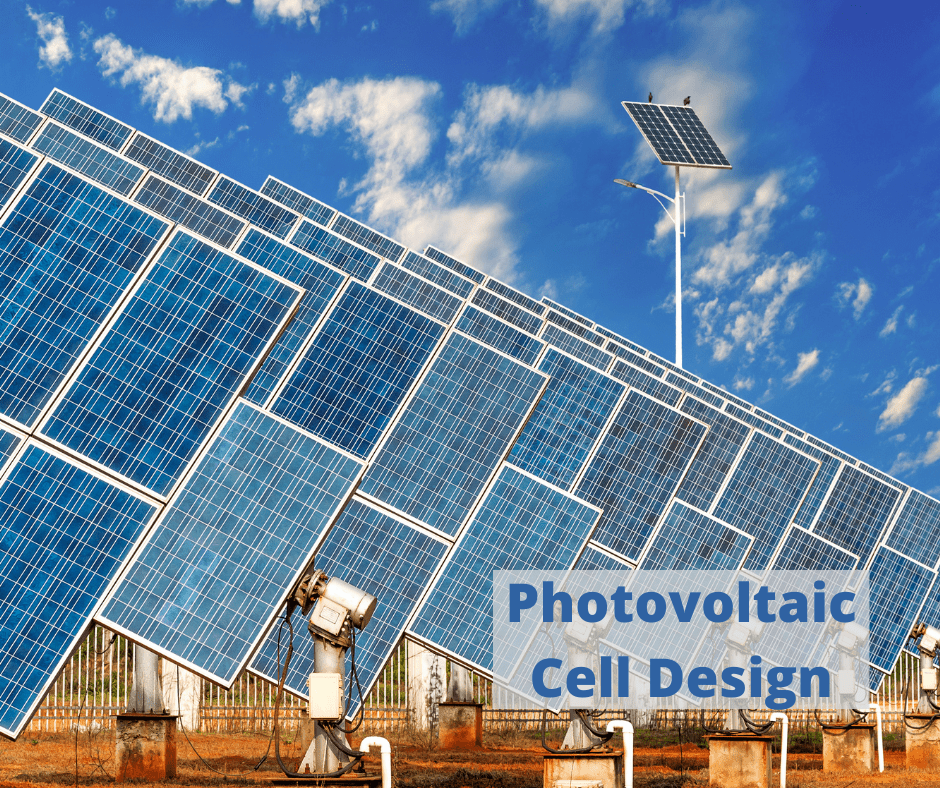

Photovoltaic Cell Design

Numerous kinds of solar cells exist. Our exploration will cover Monocrystalline silicon, Germanium, Gallium arsenide, and Dye-sensitized solar cells. When selecting the most suitable one, take into account your solar panel’s design. This article outlines the benefits of each type. Continue reading to discover the advantages and disadvantages of each. We hope you find the information useful. Should you have any inquiries, please feel free to reach out to us.

Monocrystalline Silicon

There are two major types of solar cells. Monocrystalline cells use silicon crystallized into a single monolayer, resulting in relatively high efficiency of 15 to 24 percent. Polycrystalline cells have lower efficiency but can be made in large vats and lower production costs. Another type of monocrystalline cell is called a Bifacial solar cell, which generates electricity from the front and back sides of the module. This type of cell is becoming more popular in commercial ground-mounted applications.

Solar Panel

” class=”wp-image-211″/>

Solar Panel

” class=”wp-image-211″/>

The design of the monocrystalline silicon photovoltaic cell differs from that of the multi-crystalline silicon version. The first generation of solar cells has a thickness of approximately one-tenth of an inch. It can achieve light absorption of about 0.6 volts at 25 degrees Celsius under AM1.5 illumination. These cells are connected in a series to increase power output and voltage compatible with a 12 V battery. The cells are wired together and placed behind a sheet of tempered glass. An electrically conductive adhesive connects the cell to the bus bar.

The second generation of solar cells is much thinner, about one-hundredth of an inch. They are made by vaporizing silicon in a quartz tube and depositing it on a substrate. They are also connected in a series to increase power output and voltage. The cells are wired together and placed behind a sheet of tempered glass. An electrically conductive adhesive connects the cell to the bus bar.

The third generation of solar cells is called thin-film solar cells. They are made by depositing a very thin layer of photovoltaic material on a substrate. The most common thin-film materials are cadmium telluride (CdTe) and amorphous silicon (a-Si). CdTe solar cells have an efficiency of about 10 percent. a-Si solar cells have an efficiency of about 6 percent.

The fourth generation of solar cells is called quantum dot solar cells. They are made by depositing a layer of quantum dots, tiny semiconductor crystals, on a substrate. The quantum dots are tuned to absorb specific wavelengths of light and convert them into electrical currents. Quantum dot solar cells have an efficiency of about 3 percent.

Germanium

A recent study of the Germanium photovoltaic cell demonstrates its high infrared reflectivity. The infrared reflectivity is improved by adding a passivation layer on the rear surface. A new passivation layer sequence consists of amorphous Si x C 1-x and Al layers. These layers are adapted to achieve high infrared reflectivity while reducing heat generation. These two components can improve the performance of the photovoltaic cell device and generate up to 10 percent more current.

The backside germanium solar cell is not widely used for multifunction solar cells. The backside germanium photovoltaic cell design collects longer wavelengths near the silicon band-gap. However, this type of cell design has been proposed to increase the device’s efficiency. The backside germanium cell can be more effective with a thinner silicon layer. In addition, it can absorb longer wavelengths.

The front side germanium cell has a better visible light response than the backside cell. The front side cell is also used in concentrated photovoltaic (CPV) systems. The germanium layer helps to improve the optical absorption of the incident light. It can also help to reduce surface recombination losses.

The Germanium photovoltaic cell has a high infrared reflectivity. The Germanium layer helps to improve the optical absorption of the incident light. It can also help to reduce surface recombination losses.

Germanium is a good choice for cells in space applications due to its high resistance to radiation damage. Germanium has a higher tolerance to nuclear radiation than silicon. Germanium is also a good choice for high-temperature applications. Germanium can operate at temperatures up to 900 degrees Celsius.

Gallium Arsenide

In recent years, gallium arsenide in photovoltaIC cell design has made headlines. It was used on the Mars rovers Opportunity and Valor – the first human missions to explore the planet. Due to dust storms on Mars, the conversion rates of these solar cells dropped significantly. Today, solar panels are becoming more affordable as technological advances continue. However, the downside to gallium arsenide is its price tag.

Gallium arsenide photovoltaic cells are one of the most efficient types of solar cells available. They are made of a material that can convert more of the sun’s energy into electricity than other solar cells. Gallium arsenide photovoltaic cells are also very light and thin, making them easy to install on rooftops and other surfaces.

However, they are also costly and are not yet widely used. Despite their high cost, gallium arsenide photovoltaic cells are likely to become more prevalent in the future as the price of solar energy continues to drop.

Dye-Sensitized Solar Cells

One of the lowest-cost types of solar cells is the dye-sensitized solar cell. This type is part of the thin film solar cell family and is based on a semiconductor that forms between the photo-sensitized anode and electrolyte. The dye-sensitized anode converts light into electricity through an electrochemical reaction. In this way, it is an effective photoelectrochemical system.

The DSSC method uses dye to enhance light absorption and electron transport. It also utilizes incident light energy by triggering an electron transfer reaction. One of the most significant advantages of dye-sensitized solar cells is their low cost and ease of manufacture. While most current DSSCs are made of silicon and a semiconductor, other materials such as Pt and Nb2O5 are also being investigated.

Organic Photovoltaics

Organic photovoltaic cells are used to generate energy for solar energy. They are available in various shapes, including cylinders, spheres, octagons, and other complex conditions. These modules are fabricated using a printing process and can be as large as A5. Unlike conventional cells, organic photovoltaic modules can be directly patterned, avoiding the need for post-patterning stages. However, thoroughly understanding the manufacturing process is essential for designing custom-shaped modules. Dimensional accuracy and shrinking/spreading of the ink affect the precision of the printed image.

One of the problems of organic solar cells is degradation, mainly when water and oxygen are present. These materials undergo photodegradation when exposed to oxygen and water. The formation of a ground state of atmospheric oxygen provides a degradation pathway. For this reason, organic solar cells are not yet widely used for commercial applications. The development of organic photovoltaic technology has helped in overcoming these problems. These new technologies have opened the way to customized solar cells and are now available for commercial use.

Multijunction Solar Cells

Multijunction solar cells have multiple p–n junctions. Because of this, they generate more energy. These cells are typically made from various types of semiconductor materials. However, each one has a different level of efficiency. Listed below are the differences between multijunction and conjunction solar cells. Let’s explore each type. We’ll start with multijunction solar cells. The difference is that they produce different types of energy.

Gallium arsenide-based multijunction solar cells are currently the most efficient, reaching 47.1% efficiency with a triple-junction cell. Multijunction solar cells are most efficient when made up of three layers of semiconductors. Gallium-arsenide multijunction cells are grown using a metalorganic chemical vapor deposition process. Multijunction solar cells are a promising new technology because they can use different materials to produce three various junctions on the same cell. The other materials allow for different bandgaps, which results in higher overall efficiency.

On the other hand, junction solar cells are less efficient than multijunction solar cells. They are made with only two junctions and use only two types of semiconductors. The most common type of junction solar cell is the silicon-based cell. Made with pure silicon, they can convert around 26% sunlight into electricity. However, when made with other materials, such as germanium or gallium arsenide, the efficiency can be as low as 12%.

Junction solar cells are less efficient than multijunction solar cells because they use only two types of semiconductors. The most common kind of junction solar cell is the silicon-based cell. Made with pure silicon, they can convert around 26% of sunlight into electricity. However, when made with other materials, such as germanium or gallium arsenide, the efficiency can be as low as 12%.

Junction solar cells have a lower efficiency than multijunction solar cells. They are made with only two junctions and use only two types of semiconductors. The most common junction solar cell is the silicon-based cell. Made with pure silicon, they can convert around 26% of sunlight into electricity. However, when made with other materials, such as germanium or gallium arsenide, the efficiency can be as low as 12%.

Multijunction solar cells are more efficient than junction solar cells because they have multiple p–n junctions. Because of this, they generate more energy. These cells are typically made from various types of semiconductor materials. However, each one has a different level of efficiency.

Conclusion

Multijunction solar cells are a promising new technology because they can use different materials to produce three various junctions on the same cell. The other materials allow for different bandgaps, which results in higher overall efficiency. Multijunction solar cells are made with three layers of semiconductors, while junction solar cells are made with only two. Multijunction solar cells are more efficient than junction solar cells because they have multiple p-n junctions.

Solar Cells

Solar Cells Technology – What’s Next?

The advancements in solar cell technology over the past forty years have been significant. Transitioning from silicon that is 99% pure to the development of Perovskite solar cells marks significant progress. But what lies ahead? In this article, we’re going to explore HJT cells, N-type (IBC) monocrystalline silicon, and perovskite solar cells. Examining these varied types will provide a clearer insight into what each technology brings to the table.

99% Pure Silicon

The 99% purity of silicon in solar cells is derived from metallurgical silicon, which is not semiconductor grade. 99% pure silicon is obtained by purifying metallurgical silicon using several steps. The first step is mixing powdered metallurgical silicon with hot hydrochloric acid. The resulting gas contains four attachments – a silicon atom in the center, an oxygen atom at one end, and a carbon atom in the other.

High-quality silicon has a low optical absorption coefficient, allowing the absorption of sunlight while reducing the recombination of minority carriers. 99% pure silicon has a very long diffusion length of photo-generated minority carriers, which limits the recombination rate and lowers the efficiency of solar cells. This long diffusion length makes it possible to balance competing processes while improving efficiency. Generally, higher purity silicon cells have a longer lifetime and better payback.

Perovskite Solar Cells

Metal halide perovskites are light harvesters that have recently stunned the photovoltaic community. They are a step away from the silicon-based solar cells of the past. But they don’t just harvest light. They also do so very efficiently. This development has stunned the photovoltaic community, and many experts now wonder if they can replace silicon-based solar cells with these new ones.

Recent studies on perovskite solar cells suggest a promising future for improving energy-conversion efficiency, but significant challenges remain. Perovskite solar cells contain up to five layers. Each performs a different function during the electricity-generation process. But because the layers are made of other materials, they can degrade quickly due to changes in temperature and mechanical stress. If these layers are compromised, the performance of the cell plummets.

HJT Cells

In the early 80s, researchers first developed a structure for HJT solar cells. Sanyo/Panasonic commercialized it, and by 2010, the technology had reached full technical maturity. Previously, however, this solar cell structure was still limited to small niche applications because of high production costs and high-temperature coefficients. But in recent years, a group led by the Meyer Burger Group and Prof. Christophe Ballif in Neuchatel, Switzerland, has improved this technology to a level where it is suitable for gigawatt-scale applications.

While PERC technology has remained a popular choice for many years, HJT is quickly gaining ground. Its advantages include low manufacturing costs and a high relative gain of about 10 percent over PERC. However, these advantages come at a cost. HJT solar cells technology is a long-term investment, so if you’re looking to maximize your returns on solar energy, it’s worth looking into the technology now.

III-V Solar Cells

NREL is investing in developing III-V solar cells to decrease costs and increase conversion efficiency while being suitable for both space and traditional flat plate applications. The research will address several areas, including the growth of multijunction solar cells, materials and manufacturing, tracking and concentration methods, and epitaxy. This article will discuss some ongoing projects, their benefits, and the production process. Let’s get started.

This class of semiconductors has several unique properties. They combine various materials, such as binary to quaternary compounds, and the bandgap engineering process is flexible. In addition, they tend to radiate light efficiently. These characteristics make III-V solar cells an excellent option for high-efficiency photovoltaic devices. The cost and efficiency of these solar cells are the key factors that drive their development. But, these solar cells are far from the only drawbacks.

Thin-Film Solar Cells

A thin-film solar cell is the second generation of the solar cell and is made by depositing layers of photovoltaic material on a substrate. The substrate can be glass, plastic, or metal. The thin-film solar cell has many advantages over the first-generation solar cell. This type of cell can produce power with a minimal amount of energy and is an excellent choice for solar panels. But there are some downsides as well.

One of the significant drawbacks of thin-film solar cells is the materials’ thickness. A reduction in the thickness of the material would improve efficiency and manufacturing costs. The cells would be cheaper to produce and would require less material. A new design uses an onion-like structure, with a rectangular core coated in the light-absorbing semiconductor material. Then three layers of non-absorbing, anti-reflective material cover the entire surface.

Hi, I’m David. I’m an author of ManagEnergy.tv where we teach people how to save energy and money in their homes and businesses.

I’ve been a writer for most of my life and have always been interested in helping people learn new things. When I was younger, I would write short stories for my classmates and teach them how to do math problems.

I love traveling and have been lucky enough to visit some fantastic places around the world.

-

Sustainable Supply Chain Management4 months ago

Sustainable Supply Chain Management4 months agoManagEnergy Acquires GPST2030.org Domain to Strengthen Commitment to Sustainable Transport

-

Wind Energy5 months ago

Wind Energy5 months agoHow Much Oil Does It Take To Lubricate A Wind Turbine

-

Electric Motorbike3 months ago

Electric Motorbike3 months agoCalifornia Electric Motorcycle Laws: A Comprehensive Guide to Riding Safely

-

Solar4 months ago

Solar4 months agoIn 2009, About What Percent Of U.S. Energy Consumption Was Supplied By Solar Energy

-

Electricity Vehicle3 months ago

Electricity Vehicle3 months agoThe Future of Electric Vehicles: Trends and Innovations to Watch

-

Wind Energy3 months ago

Wind Energy3 months agoRevolutionizing Highways: Wind Turbines Take the Road to Renewable Energy

-

Solar4 months ago

Solar4 months agoWhy Should We Use Solar Energy Instead Of Fossil Fuels

-

Solar4 months ago

Solar4 months agoHow Much Solar Energy To Go Off The Grid